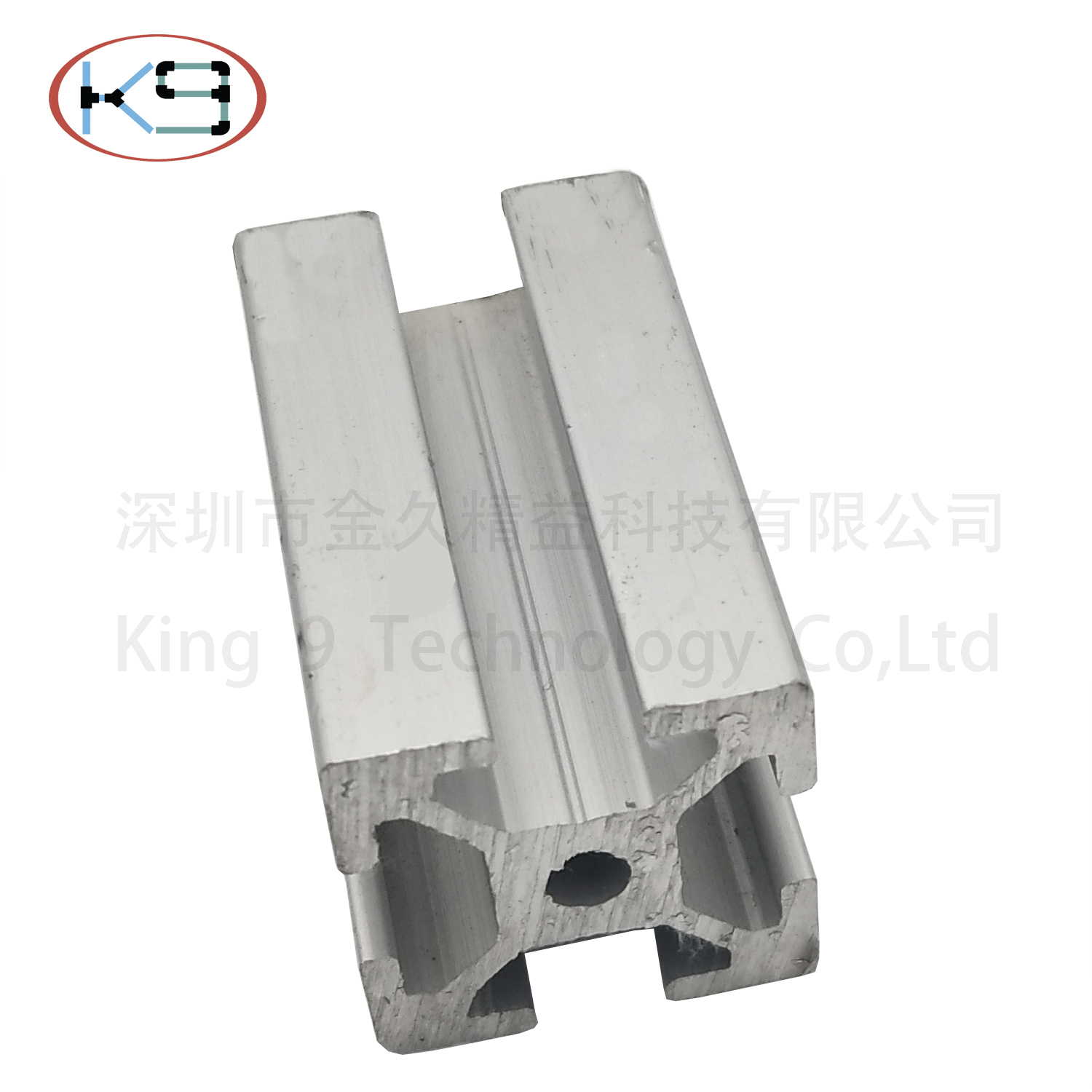

As a China Aluminum Rack System Supplier, let us explain why the surface of the Aluminum Tube System is rough and how to solve it.

If the internal defects of the aluminum profile cause surface roughness: cast state structure, such as cast or die-cast aluminum workpiece; aluminum profile grain refinement is insufficient and loose, slag inclusion defects; insufficient deformation during processing, pine branches, etc. The defect causes the surface to be rough, which can be prevented by improving the internal quality of the aluminum profile. Therefore, the production process of aluminum profile manufacturers is particularly important to improve the surface quality of chemical polishing.

Aluminum Tube System chemical polishing of the surface of the aluminum surface may be rough due to the defect may be caused by too high levels of nitric acid in the bath, acid erosion; there may be surface roughness caused by internal defects in the aluminum profile.

If the copper content in the bath is also high, the surface roughness will be more serious. Usually, if the content of nitric acid in the bath is too high, the chemical polishing is severe and a "boiling" phenomenon occurs. If the content of nitric acid is normal and the copper content is high, a characteristic color of metallic copper adheres to the surface of the washed Aluminum Tube System. If the characteristic color of copper is very deep, the copper content in the surface bath is too high, and measures should be taken to adjust the content of nitric acid and copper to the normal range. If the additive contains copper, it should be added less; if the copper in the bath comes from the chemical polishing of the copper-containing aluminum profile, take measures to add the copper-free additive or adjust the bath.

Sign up to receive our newsletter and exclusive discounts and offters.