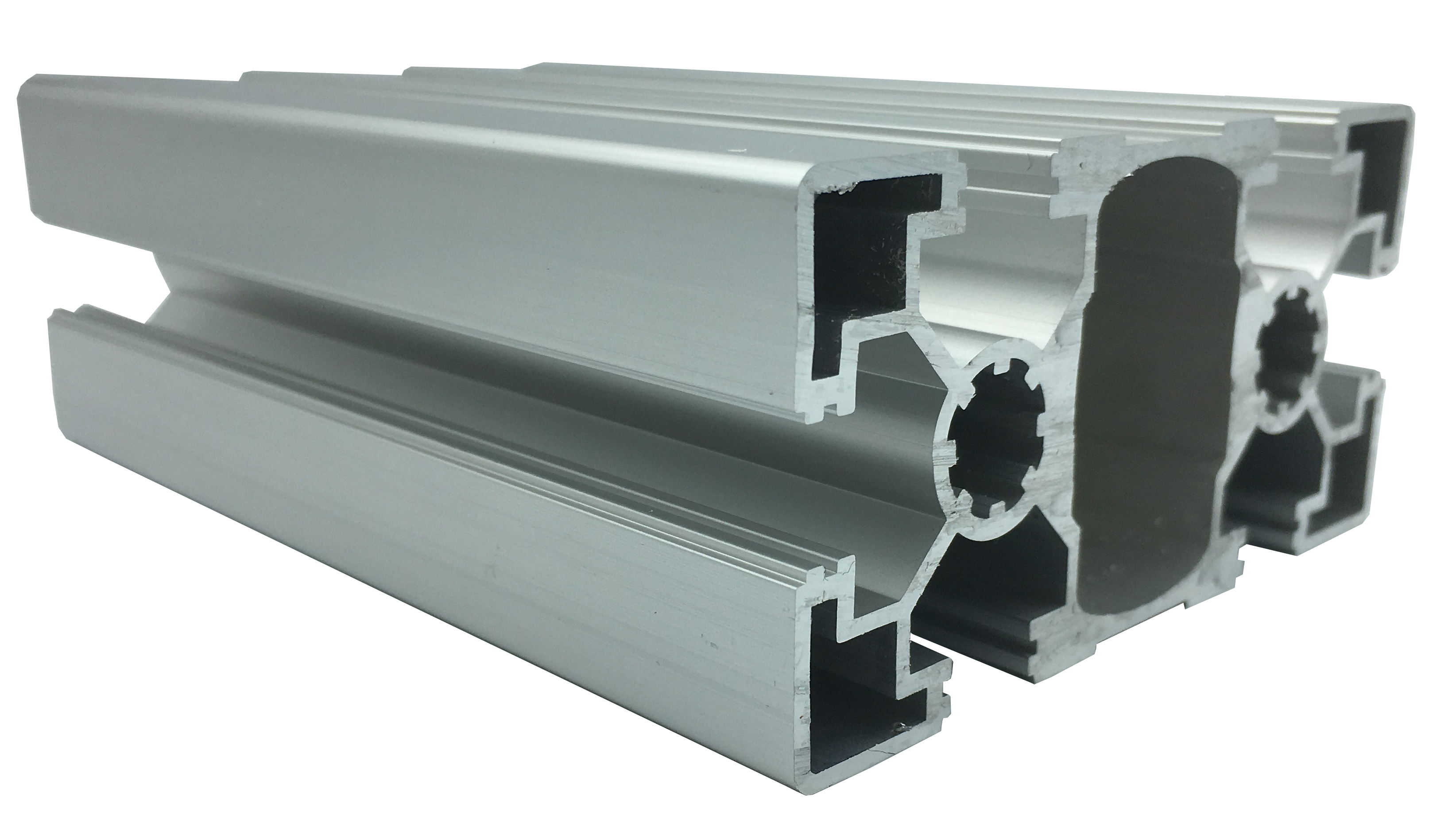

The field of extrusion of aluminum profiles in our daily lives is relatively extensive, mainly used in interior decoration. The structural properties of this extruded aluminum profile are relatively stable and relatively resistant to corrosion. The only downside is that sometimes the surface of the extruded aluminum profile will foam, so what is the cause of this situation? As a High Quality Lean Coated Tube Supplier, let's summarize it for everyone.

Causes of air bubbles and peeling of extruded aluminum profiles

1. Excessive wear of the extrusion tube and the extrusion pad, improper matching of the size of the extrusion tube and the pressing pad, and the difference in the diameter of the used gasket exceeds the allowable value;

2. The extrusion cylinder and the extrusion pad are too dirty, and are stuck with oil, moisture, graphite, etc.;

3. There are too many shovel grooves on the surface of the ingot, too deep, or there are pores, blisters on the surface of the ingot, loose structure and oil stains;

4. When the alloy is replaced, the inside of the cylinder is not cleaned;

5. The ingot is too long, the filling is too fast, the temperature of the ingot is not uniform, causing non-drum filling, so the exhaust in the cylinder is not complete, or the operation is improper, and the exhausting process is not performed;

6. The die hole design is unreasonable, or the residual material is improperly cut, and the residual material in the split hole and the flow guiding hole is partially taken out, and the gas in the gap enters the surface when pressed.

Our company provides the Aluminium Profile System. Welcome to contact us.

Sign up to receive our newsletter and exclusive discounts and offters.